Ianadmin

Xerium Introduces CemPress Polyurethane Roll Cover Technology for Fibre Cement Machines

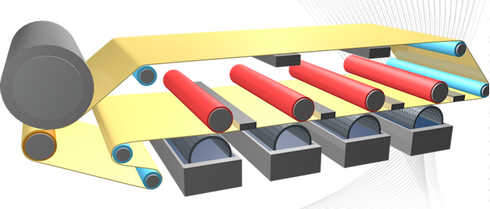

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, recently launched CemPress polyurethane roll technology for drive roll applications on fibre cement machines. CemPress utilizes an innovative compound with special processing which delivers excellent wear resistance for fibre cement machines that use highly abrasive materials in their processing. CemPress is also ideal for machines requiring resistance to high pH and caustic chemical processes. CemPress roll technology is also the best application for those machines operating in low or high temperature environments.

"Recently developed by Xerium's Stowe Woodward R&D team, CemPress is another product innovation for the fibre cement industry where Xerium has deep roots," said Mr. Bill Butterfield, EVP and CTO of Xerium. "We are excited to expand our technology across multiple industries and see more customers becoming more competitive through the use of this new class of polyurethane that will enhance machine performance and roll cover life."

ABOUT Xerium

Xerium Technologies, Inc. (NYSE:XRM) is a leading global provider of industrial consumable products and services. Xerium utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to production, all designed to optimize performance and reduce operational costs. Xerium has 27 manufacturing facilities in 12 countries around the world and employs approximately 3,200 employees.

Learn more about CemPress at http://www.xerium.com/news/xerium-news.aspx.

Xerium Introduces EnduraStar Felt Technology for Fibre Cement Machines

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, recently launched its EnduraStar felt technology for application on fibre cement machines. EnduraStar felts are designed especially for those demanding machines where high running tensions are required due to process or extended machine length. EnduraStar uses special machine direction and cross machine direction yarns that deliver exceptional machine direction strength while the fine top surface is engineered to provide a smooth, marking-free surface for optimum sheet quality. EnduraStar's feature set is specifically tailored to improved operational performance, durability, and with enhanced felt life potential.

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, recently launched its EnduraStar felt technology for application on fibre cement machines. EnduraStar felts are designed especially for those demanding machines where high running tensions are required due to process or extended machine length. EnduraStar uses special machine direction and cross machine direction yarns that deliver exceptional machine direction strength while the fine top surface is engineered to provide a smooth, marking-free surface for optimum sheet quality. EnduraStar's feature set is specifically tailored to improved operational performance, durability, and with enhanced felt life potential.

"We are very proud to introduce EnduraStar, another new product breakthrough, for the fibre cement industry," said Mr. Bill Butterfield, EVP and CTO of Xerium. "This product is in direct response to what our most demanding customers have asked us for, a high strength fiber cement felt with industry leading product side smoothness, and we are delighted to see how EnduraStar is now resolving some age-old problems on some of the industry's toughest positions."

ABOUT XERIUM

Xerium Technologies, Inc. (NYSE:XRM) is a leading global provider of industrial consumable products and services. Xerium utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to production, all designed to optimize performance and reduce operational costs. Xerium has 27 manufacturing facilities in 12 countries around the world and employs approximately 3,200 employees.

Learn more about EnduraStar fibre cement felts at http://www.xerium.com/news/xerium-news.aspx.

North American Papermaker Signs Commercial Agreement to Deploy Minerals Technologies' FulFill® High Filler Technology

Company's Sixth Commercial Agreement for the FulFill® Technology in North America

Minerals Technologies Inc., has announced that it has signed a commercial agreement with a North American paper company to provide FulFill® E-325 High Filler Technology. This agreement, which will deploy the technology at a paper mill that produces woodfree paper, is Minerals Technologies' sixth in North America. The paper company wishes to remain unnamed for competitive reasons.

Minerals Technologies Inc., has announced that it has signed a commercial agreement with a North American paper company to provide FulFill® E-325 High Filler Technology. This agreement, which will deploy the technology at a paper mill that produces woodfree paper, is Minerals Technologies' sixth in North America. The paper company wishes to remain unnamed for competitive reasons.

The company now has 18 agreements with paper mills that have adopted the unique FulFill® E-325 technology introduced in late 2010. The FulFill® technology provides papermakers significant cost savings in reduced fiber consumption by allowing papermakers to increase loading levels of precipitated calcium carbonate (PCC), which replaces higher cost pulp, and increases PCC usage.

"Our FulFill® technology continues to gain acceptance across the worldwide paper industry," said Joseph C. Muscari, chairman and chief executive officer. "We are extremely pleased that another paper company has elected to deploy our technology, which is a further verification of its broad-based effectiveness. Minerals Technologies now has commercial agreements with papermakers in Asia, Europe, Latin America, North America and South Africa and are actively engaged with an additional 20 paper mills worldwide. We will continue our commitment to advance our technological leadership with papermakers around the globe."

PCC is a specialty pigment for filling and coating high-quality paper. By substituting Minerals Technologies' PCC for more expensive wood fiber, customers are able to produce brighter, higher quality paper at lower cost. In 1986, Minerals Technologies originated the satellite concept for making and delivering PCC on-site at paper mills and the concept was a major factor in revolutionizing papermaking in North America. Today, the company has 62 satellite plants in operation or under construction around the world and continues to lead the industry with consistent quality and technical innovation.

New York-based Minerals Technologies Inc. is a resource- and technology-based growth company that develops, produces and markets worldwide a broad range of specialty mineral, mineral-based and synthetic mineral products and related systems and services. MTI serves the paper, foundry, steel, environmental, energy, polymer and consumer products industries.

For further information about Minerals Technologies Inc. look on the internet at http://www.mineralstech.com/

Chinese Vinda Ltd. boosts its capacity with several repeated orders to Toscotec S.p.A.

In the last two years, the close partnership between the Hong Kong based giant tissue producer Vinda International Holdings Ltd's and the Italian leader tissue machinery Supplier Toscotec S.p.A., has delivered exceptional results: over 20 new TMs have been started up with a variety of models and drying configurations. This allowed the Vinda Group to double its production capacity reaching over 900,000 tpy tissue production.

Established in 1985, Vinda Group has grown from a small private company into a leading manufacturer and branded provider of quality household paper products in the PRC and Hong Kong. Vinda is today, with major shares from Swedish based group SCA, the third largest hygiene paper manufacturer in the PRC, with excellent performance in customer loyalty and satisfaction. With 9 manufacturing plants strategically located in different parts of the country, it serves the entire PRC, Hong Kong and Macau and exports to Australia, Singapore, Vietnam, Cambodia, Africa.

The first orders placed by the Chinese producer in year 2012 featured Toscotec’s Modulo Plus ES, with 12 ft TT SYD, a compact, modular and cost-effective machine concept with superior energy saving features. The most recent orders were for Toscotec’s advanced, high-performance tissue machines, the Ahead 2.0 ES, with 18 ft SYD.

The first orders placed by the Chinese producer in year 2012 featured Toscotec’s Modulo Plus ES, with 12 ft TT SYD, a compact, modular and cost-effective machine concept with superior energy saving features. The most recent orders were for Toscotec’s advanced, high-performance tissue machines, the Ahead 2.0 ES, with 18 ft SYD.

The key to this continuous success is represented by the great advantages in energy savings granted by Toscotec’s state of the art technology and its “TT DOES” solution, the Drying Optimization for Energy Saving.

TT DOES relies here, like in most of the orders secured to the Italian Supplier in China, exclusively on steam, the cost-effective energy source in the region, and delivers the lowest possible energy consumption.

Through the wide application and fine tuning of this solution over the years, Toscotec has now achieved the lowest consumption figures of the tissue industry, matched with the highest machine performance and runnability.

The increase in drying capacity translates directly into an increase in production output in the mill with an important side effect to reduce carbon footprint emissions.

In China since 2003, in a few years Toscotec has established itself as a leading tissue machine supplier catering to top Chinese producers. This is also the result of the recent investment effort and major steps taken by the Lucca manufacturer in establishing a new organization in China, Toscotec Paper Machine (Shanghai) Co., Ltd.

Started up in 2012, the Shanghai-based affiliate operates as Toscotec’s Sales & Customer Care Center for the entire Asian market.

L.C. Paper started up PM2 rebuild by Toscotec in Besalu, Spain

Besalu, Catalunya (Spain) - At the beginning of October 2014 the Spanish Company L.C. Paper 1881 has started up PM2 in Besalu, (Catalunya – Spain) after a major dry-end rebuild with Toscotec and its associate Milltech.

The rebuild project target was mainly to reduce PM2 energy costs and improve paper machine efficiency as well as increase the production at higher tissue grades thanks to the application of TT DOES (Drying Optimization for Energy Saving) package.

LC Paper was formed in 1881 on the back of the Industrial Revolution and is now well regarded for its production of niche tissue products contained with two tissue machines (PM2 and PM3) annually producing 65,000 tonnes of tissue for the AfH market. The main focus of the mill is toward energy saving aspects and for this reason since many years the Company has been focused on cogeneration applications.

LC Paper was formed in 1881 on the back of the Industrial Revolution and is now well regarded for its production of niche tissue products contained with two tissue machines (PM2 and PM3) annually producing 65,000 tonnes of tissue for the AfH market. The main focus of the mill is toward energy saving aspects and for this reason since many years the Company has been focused on cogeneration applications.

Already in 1993, LC Paper introduced in the mill a cogeneration plant. It was the first plant with a diesel engine of 6.5 MW in Spain that was expanded in 1999 with a second 6 MW engine.

In 2009 LC Paper launched PM3 with a patented process that takes gas from the cogeneration plant to dry the paper by the means of an innovative hood provided already by Milltech. In 2011 the first diesel engine was sold and in 2012 LC paper installed a new gas engine. 6 MW of this energy have been used for feeding the new hood by Milltech on PM2 with a further decrease of energy consumption.

The combined scope of supply Toscotec/Milltech featured a new double presses configuration with a rebuild of the felt run, a new TT SYD-15FT with doctoring system and a Duo-system Yankee hood, SMART eMT type from Milltech. The wet end hood is burner feeding type while the dry end hood could be fed either by cogeneration gases or by conventional burner.

The combined scope of supply Toscotec/Milltech featured a new double presses configuration with a rebuild of the felt run, a new TT SYD-15FT with doctoring system and a Duo-system Yankee hood, SMART eMT type from Milltech. The wet end hood is burner feeding type while the dry end hood could be fed either by cogeneration gases or by conventional burner.

So the exhaust gases coming from a gas engine are used to generate two stages of steam (high and low pressure) through steam generators in addition to the heat recovery to pre-heat the make-up and combustion air for the hood.

Maximum drying production with a machine trim width at reel of 3050 mm will be 130 tpd. With this new intervention the PM2 thermal consumption will be lowered to 1,350 kWh/t.

The rebuild project has been successful thanks to the close collaboration between the L.C. Paper staff and Toscotec and Milltech teams which were able once more to introduce innovative solutions to the tissue production process in accordance with LC Paper business philosophy.

Renewed PEFC- certification for Södra

Södra has been granted renewed forestry and chain of custody certification under the PEFC (Programme for the Endorsement of Forest Certification) for the next five years. An external audit has been performed and nearly 60 properties were inspected in 2014. The audit encompasses social, environmental and production-related issues.

Södra has been granted renewed forestry and chain of custody certification under the PEFC (Programme for the Endorsement of Forest Certification) for the next five years. An external audit has been performed and nearly 60 properties were inspected in 2014. The audit encompasses social, environmental and production-related issues.

PEFCTM certification provides assurance that forest management activities are conducted in accordance with the requirements stipulated in the PEFC's forestry standard and that the timber can be traced back to the original forest where it grew. PEFC-certified raw material is a sought-after commodity by many customers active in the areas of pulp, sawn timber and interior wood products.

"We are proud of the work that all of our members and employees put in to maintain a high level of quality in forest management activities, in terms of both production and the environment. This certification represents acknowledgement of the progress we are making," said Håkan Larsson, President, Södra Skog.

As part of its commitment to comply with the requirements of the certification scheme, Södra's members have set aside an average of 8 per cent of their forest land area for nature conservation purposes. This is equivalent to about 200,000 football pitches. Furthermore, in conjunction with harvesting operations in production forests, consideration is given to various nature conservation values, such as dead wood, old trees and valuable microhabitats.

To obtain certification, it is also necessary to meet social requirements in relation to, for example, employment terms and conditions, work environment and outdoor life.

Between them, Södra's members own 22,000 smallholdings totalling 1.7 million hectares of forest land. Södra has offered them the opportunity to gain PEFC acceditation since 2000.

Södra has also offered FSC® certification since 2009 and holds one of the world's largest group certificates.

To find out more, please contact:

Håkan Larsson, President, Södra Skog, Tel: +46 70 589 45 10

Tomas Rahm, Environmental Manager, Södra Skog, +46 470 893 33

Holmen: New Product Reduces Newsprint Capacity

![]() Holmen Paper (STO:HOLMA)(STO:HOLMB) is launching a new product in the SC segment in spring 2015, which will reduce the company’s production of newsprint. “This new initiative will quickly bring about a significant change in newsprint volumes,” comments sales and marketing director Karolina Svensson.

Holmen Paper (STO:HOLMA)(STO:HOLMB) is launching a new product in the SC segment in spring 2015, which will reduce the company’s production of newsprint. “This new initiative will quickly bring about a significant change in newsprint volumes,” comments sales and marketing director Karolina Svensson.

Intensive preparations are under way on PM 53 at Braviken Paper Mill outside Norrköping, Sweden, for the conversion work that is scheduled to begin at the end of January next year. PM 53 is Braviken’s largest machine, with an annual capacity of 310 000 tonnes for the current product mix. The machine produces Holmen NEWS (newsprint) and Holmen XLNT – the uncoated magazine paper that makes up Holmen Paper’s single biggest product family.

It is the production of newsprint for export outside the Nordic region that is going to be reduced when the new product is introduced next year.

“We are predicting a rapid rise in volumes for the new product,” says Karolina Svensson. “The aim is to achieve an annualised running rate for production and sales of more than 100 000 tonnes by the end of 2015.

“We’ll be reducing the production of newsprint at a corresponding rate, and in the longer term we’ll only keep the volumes to supply our local markets in Scandinavia.”

Holmen Paper judges that its own measures, combined with previously announced capacity closures elsewhere in the market, will considerably improve capacity utilisation for newsprint in 2015.

Holmen is a forest industry group that manufactures printing paper, paperboard and sawn timber and runs forestry and energy production operations. In 2013 Holmen’s net sales were approx. SEK 16 billion and the group has approx. 3,700 employees. Holmen’s shares are listed on Nasdaq Stockholm, Large Cap. For more information, visit www.holmen.com

This is information that Holmen AB is obliged to disclose under the Swedish Securities Market Act and the Swedish Financial Instruments Trading Act. The information was submitted for publication on 19 November 2014 at 14.00 CET.

Contacts

Holmen

Jonas Lindell

Communications Manager

tel. +46 (0)70-323 20 13

E-mail This email address is being protected from spambots. You need JavaScript enabled to view it.

Valmet receives its fourth tissue line order from ICT to Poland

Valmet will supply a complete tissue production line to ICT Poland. The new Advantage DCT 200HS tissue line will be installed at the company's mill in Kostrzyn, Poland and will fit ICT's intention to adopt state of the art technology for their tissue production. The start-up is planned for the fourth quarter of 2015.

The order is included in Valmet's fourth quarter 2014 orders received. The value of the order will not be disclosed.

Valmet has previously delivered three tissue lines to ICT companies in Italy and France. The latest, an Advantage DCT 200+ line, started up at the Montargis mill, France, in July 2011.

"Our team is very pleased and eager to work with Valmet on our machine number three in ICT Poland. We look forward to a real success story from every point of view," says Riccardo Baccelli, Executive Director, ICT.

"We have a long and fruitful relation with ICT and are happy to have been trusted to deliver our fourth tissue line, this time to Poland. We are looking forward working together as a team to make this a successful project," says Jan Erikson, VP Sales, Tissue Mills business unit, Valmet.

Valmet's scope of delivery will comprise of a complete tissue production line including a stock preparation system and an Advantage DCT 200HS tissue machine with the latest technology for highest quality consumer tissue. The production line will be optimized to save energy and enhance final product quality.

Complete engineering, training, start-up and commissioning are part of the delivery. The delivery will also include an extensive automation package from Metso.

The new line will add 70,000 tons a year of high-quality toilet and towel grades for the European market. The raw material for the new line will be virgin fiber.

Information about ICT

ICT, established in 1957, entered the tissue business in 1978. Today the company operates nine tissue lines in four European countries; five machines in Italy, one in Spain, two in Poland and one in France. The global production capacity of the ICT group currently amounts to about 470,000 tons per year of toilet, kitchen, facial and napkin tissue, and the total number of employees of the Group is approximately 1,300 persons.

For further information, please contact:

Jan Erikson, Vice President, Sales, Tissue mills Business Unit, Valmet, Tel. +46 70 517 14 90

Johan Björn, Sales Manager, Tissue mills Business Unit, Valmet, Tel. +46 703 17 12 16

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 11,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

The company has over 200 years of industrial history and was reborn through the demerger of the pulp, paper and power businesses from Metso Group in December 2013. Valmet's net sales in 2013 were approximately EUR 2.6 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Read more www.valmet.com , www.twitter.com/valmetglobal

UPM Kymi celebrated its pulp mill expansion investment topping out ceremony

UPM Kymi celebrated the topping out ceremony for its pulp mill production expansion project, KYMI700: the new pulp drying machine, debarking plant and modernisation of the softwood fibre line. A total of around 200 participants are invited in the celebrations including those working on the project and guests.

UPM Kymi celebrated the topping out ceremony for its pulp mill production expansion project, KYMI700: the new pulp drying machine, debarking plant and modernisation of the softwood fibre line. A total of around 200 participants are invited in the celebrations including those working on the project and guests.

UPM invests € 160 million into the Kymi pulp mill to strengthen its position in the growing end use sectors of the global pulp market, namely tissue, speciality papers and packaging board. Following this investment, Kymi’s annual pulp production capacity will increase by 170,000 tonnes to 700,000 tonnes of bleached northern softwood and birch pulp.

The investment at Kymi mill will comprise a new pulp drying machine, modernisation of the softwood fibre line, a new debarking plant as well as improvements in the energy balance of the Kymi integrate consisting of pulp and paper mills.

Construction progressing well alongside normal production

The construction work that began in June is on schedule. At the moment, around 150 people are working in different project sites. The current and initial jobs are, among others, laying foundations, steel construction installation, painting, tank and pulp tower installations, as well as demolition work at the softwood fibre line. Machine installation will take place in January. The most significant construction contracts have been given to businesses located in the northern part of the Kymenlaakso region.

"The biggest challenge has been the pulp drying machine. The demolition of the old machine hall, including land construction work and implosions, has been successful, while paper production has been ongoing in the same location. We can be especially pleased that we have achieved this with no accidents in any project area that would have resulted in sick leave. We emphasise the importance of safety measures at our sites, and the construction firms take it seriously," says project manager Tero Ojala.

At its largest, the construction team will number 800 people next summer when the new facilities become operational. The project will be completed in the autumn of 2015.

The investment and construction works have a positive effect on the employment and businesses in the region. The increasing use of wood in the mill integrate will bring wood harvest and transportation work for forest industry professionals and earnings for forest owners.

After its completion, UPM Kymi will be one of the most modern pulp mills in Finland, together with the € 360 million pulp mill chemical recovery plant completed in 2008.

For further information, please contact after 16:30 EET:

Markku Laaksonen, General Manager, UPM Kymi, tel. +358 (0)400 754 649, This email address is being protected from spambots. You need JavaScript enabled to view it.

Tero Ojala, Project Manager, UPM Kymi-700 project, tel. +358 (0)40 7033817, This email address is being protected from spambots. You need JavaScript enabled to view it.

UPM, Media Desk

Tel. +358 (0)40 588 3284

Mon–Fri from 9:00–16:00

This email address is being protected from spambots. You need JavaScript enabled to view it.

www.twitter.com/UPM_News

www.facebook.com/UPMGlobal

UPM Kymi

UPM Kymi is an environmentally efficient mill integrate producing pulp, paper and energy. UPM Kymi employs about 600 people and is located in south-east Finland in Kuusankoski, Kouvola. Kymi produces bleached birch and softwood pulp as well as coated and uncoated fine paper.

The integrated annual pulp production capacity is approximately 530,000 tonnes and paper production capacity is approximately 830,000 tonnes. The completion of the ongoing expansion investment in 2015 will increase the annual pulp production capacity to 700,000 tonnes.

UPM Pulp

UPM is one of the world’s leading producers of northern softwood, birch and eucalyptus pulp supplying global customers mainly in the growing end use sectors such as tissue, specialty papers and packaging board through its own sales and technical service network close to its customers. UPM Pulp employs approximately 1500 people. UPM Pulp operates four modern pulp mills, three in Finland and one in Uruguay, as well as eucalyptus plantations in Uruguay. The Kymi investment increases the annual pulp production capacity of UPM’s pulp mills to 3.5 million tonnes. Pulp Business is part of the UPM Biorefining Business Area. www.upmpulp.com

UPM

UPM leads the reformation of bio and forest industries. We are building a sustainable future in six business areas: UPM Biorefining, UPM Energy, UPM Raflatac, UPM Paper Asia, UPM Paper Europe and North America, and UPM Plywood. Our products are made of renewable raw materials and are recyclable. We serve a global base of customers. We employ approximately 21,000 people and our annual sales are approximately € 10 billion. UPM's shares are listed on NASDAQ OMX Helsinki. UPM – The Biofore Company – www.upm.com

Xerium Celebrates 500th Order for Its SMART(R) Technology Nip Monitoring and Machine Automation System

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, recently received its 500th order for its proprietary SMART® Technology system. The globally successful and patented machine automation system continues rapid growth on traditional paper, paperboard, and tissue machines but also has now been successfully applied on numerous other nipped applications in nonwovens and the building products industries. The latest generation of SMART Technology dynamically measures and displays: machine direction nip width, machine direction pressure profile, and cross machine direction pressure profile. It also includes enhanced connectivity software for mill computer systems and supports multi-nip roll positions for unprecedented simultaneous analysis. SMART Technology has been equally successful across all paper grades, including tissue, and even on the most demanding shoe press applications. In addition, SMART Technology is now being successfully applied on suction roll applications which customers have long been requesting.

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, recently received its 500th order for its proprietary SMART® Technology system. The globally successful and patented machine automation system continues rapid growth on traditional paper, paperboard, and tissue machines but also has now been successfully applied on numerous other nipped applications in nonwovens and the building products industries. The latest generation of SMART Technology dynamically measures and displays: machine direction nip width, machine direction pressure profile, and cross machine direction pressure profile. It also includes enhanced connectivity software for mill computer systems and supports multi-nip roll positions for unprecedented simultaneous analysis. SMART Technology has been equally successful across all paper grades, including tissue, and even on the most demanding shoe press applications. In addition, SMART Technology is now being successfully applied on suction roll applications which customers have long been requesting.

More information about SMART Technology is available at http://www.xerium.com/markets-products/pulp,-paper-tissue/smart-technology.aspx

"SMART Technology continues to provide our customers with critical information they need to instantly monitor, adjust, and troubleshoot their machines which historically was a static process requiring costly machine downtime," said Mr. Bill Butterfield, EVP and CTO of Xerium. "Xerium has developed SMART technology to benefit its customers by lowering their operational cost while improving operational efficiency. Together we are always discovering more potential for SMART Technology applications and are excited at the way our customers have embraced this innovative approach to machine automation."

ABOUT XERIUM

Xerium Technologies, Inc. (NYSE:XRM) is a leading global provider of industrial consumable products and services. Xerium utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to production, all designed to optimize performance and reduce operational costs. Xerium has 27 manufacturing facilities in 12 countries around the world and employs approximately 3,200 employees.

Xerium Technologies, Inc.

Steve Cole

Director - Global Marketing

001-919-526-1447

This email address is being protected from spambots. You need JavaScript enabled to view it.