Ianadmin

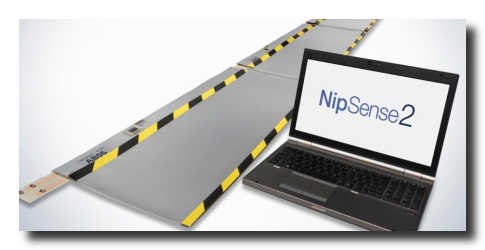

NipSense2: New system from Voith facilitates static real-time measurement in the roll nip

With NipSense2, Voith has developed a new analytic system through which the invisible nip conditions of two rolls can be visualized and measured in real time. The system performs corrective calculations of the nip profile and thus contributes to a substantial improvement of the reliability and quality of the paper manufacturing process.

NipSense2 gives a clear view of the otherwise invisible contact point of two rolls. Through very precise sensors that are placed between two rolls, the nip width can be determined with a high degree of measurement accuracy. The sensors transmit data wirelessly to the analytical software. The closing process of the press rolls and every change in nip width becomes visible on the screen. The entire measurement process can be stored on video and later replayed. An expert report with crown recommendations completes the service.

NipSense2 is able to measure all roll types, regardless of roll length and diameter. The new measurement technology is able to measure several nips at the same time and so discover previously unknown interdependencies. The nip profile can be optimized by using NipSense2. Thanks to more uniform paper and moisture profiles, the profile optimizations lead to a longer service life of the roll covers and, thanks to reduced errors in the roll hydraulics, to a more efficient paper manufacturing process.

Further information is available on the Voith website at www.voith.com/paper. Voith Paper is also on Twitter and YouTube.

Voith Paper is a division of the Voith Group and the leading partner to and pioneer in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-saving products to reduce the use of energy, water, and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

Voith sets standards in the markets energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, Voith employs more than 43,000 people, generates € 5.7 billion in sales, operates in about 50 countries around the world and is today one of the biggest family-owned companies in Europe.

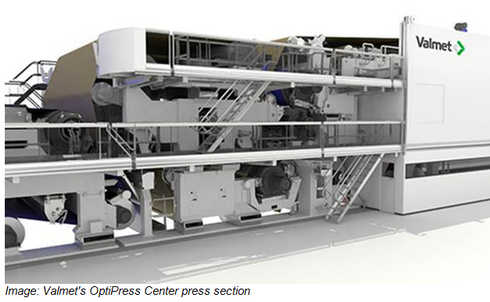

Valmet to supply a press section rebuild for Mondi Štêtí in Czech Republic

Valmet will rebuild a sack kraft paper machine at Mondi's Štêtí mill in Czech Republic. Valmet's delivery for the paper machine 5 (PM5) will include the modernization of the press section. The targets of the rebuild are increased production efficiency and improved machine runnability, while ensuring safe working environment. The rebuilt production line will start-up during the fourth quarter of 2015.

The order was included in Valmet's third quarter 2014 orders received. The value of the order is not disclosed.

"Our target was to have a reliable high performing press concept for our PM 5. Valmet was able to offer their OptiPress concept which provides a balance of a well proven technology with innovative technical solutions. The further development of this press type provides also for the operators the possibility to operate and maintain the press in a safe and efficient way," says Lars Mallasch, Technical Director Packaging Paper, Head of Capital Expenditure Mondi E&I.

"We have strong track record on modularly designed and built paper and board lines and the same modular approach can be utilized in rebuilds too. For customers, this means resource saving solutions that are fast to install and safe to use and maintain," says Reijo Koivuranta, Press Sections Product Manager at Valmet.

Key features of the delivery

The existing press section at PM5 will be rebuilt into OptiPress Center press section. With this tri-nip solution, the new 1st press, the 2nd press and the 3rd press shoe nip maximizes the dry content entering the dryer section and increases the wet strength of the paper. The resulting boost in dryness thus fully benefits web runnability in the open draw and in the beginning of the dryer section. Felt conditioning is done effectively with uhle boxes equipped with perforated covers. This results in improved dewatering and lower energy consumption.

The simplified frame construction of modular press section design means low load to foundation, space savings, shorter shutdown and faster installation. Fabric changes are possible with the help of a fabric insertion unit, as there is no cantilevering. User friendly design like new walkways emphasize safety and easy maintenance.

The rebuild also includes a new press pulper and modifications at the dryer section.

Information about Mondi

Mondi is an international packaging and paper Group, employing around 26,000 people in production facilities across 31 countries. In 2013, Mondi had revenues of €6.5 billion and a ROCE of 15.3%. The Group's key operations are located in central Europe, Russia, the Americas and South Africa.

Mondi Štêtí a.s. is a manufacturer of high grade sack kraft and speciality kraft paperMondi Štêtí a.s. is located in Štêtí, on the banks of the Elbe River, 40 kilometres north of Prague, Czech Republic. Mondi Štêtí a.s. now annually produces more than 500,000 metric tons of pulp, paper and board of world-class quality that are sold on all continents.

For further information, please contact:

Hannu Mälkiä, Area President, EMEA, Valmet, Tel. +358 400 460 587

Reijo Koivuranta, Product Manager, Press Sections, Valmet, Tel. +358 40 536 6753

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 11,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

The company has over 200 years of industrial history and was reborn through the demerger of the pulp, paper and power businesses from Metso Group in December 2013. Valmet's net sales in 2013 were approximately EUR 2.6 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Read more www.valmet.com , www.twitter.com/valmetglobal

KapStone's Charleston Mill Efficiency Plans

KapStone Paper and Packaging Corporation (NYSE: KS) ("KapStone" or "the Company") As part of KapStone's periodic review with our community constituents, KapStone shared a capital investment plan for the North Carolina paper mill with the Economic Development Commission. The multi-year investment plan, which totaled approximately $115 million, included the recently completed $29 million upgrade to paper machine number three as well as a range of anticipated capital projects that will maintain the mill's cost competitiveness and efficiencies over multiple years by modernizing the three existing paper machines.

KapStone Paper and Packaging Corporation (NYSE: KS) ("KapStone" or "the Company") As part of KapStone's periodic review with our community constituents, KapStone shared a capital investment plan for the North Carolina paper mill with the Economic Development Commission. The multi-year investment plan, which totaled approximately $115 million, included the recently completed $29 million upgrade to paper machine number three as well as a range of anticipated capital projects that will maintain the mill's cost competitiveness and efficiencies over multiple years by modernizing the three existing paper machines.

About the Company

Headquartered in Northbrook, IL, KapStone Paper and Packaging Corporation is the fifth largest producer of containerboard and corrugated packaging products and is the largest kraft paper producer in the United States. The Company is the parent company of KapStone Kraft Paper Corporation and KapStone Container Corporation which includes four paper mills and 22 converting plants, respectively, across the US. The business employs approximately 4,600 people.

SOURCE KapStone Paper and Packaging Corporation

Andrea K. Tarbox, Vice President and Chief Financial Officer, 847.239.8812

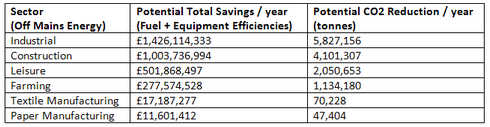

British Paper Manufacturing Sector Wastes Almost £12 Million A Year On Outdated Energy Sources

A new report out this week has revealed that the British paper manufacturing sector wastes a huge £12 million each year by using outdated off-mains energy sources.

- Sector currently spends over £43 million a year on oil

- Despite falling oil prices, sector could save £11.6 million / year by switching energy sources

- Switch could reduce industry CO2 emissions by 47,000 tonnes

The sector currently spends almost £43 million a year on oil for its heating, lighting and manufacturing processes.

Even though oil prices are currently falling, new research suggests this figure can still be cut dramatically to around £31 million by switching to LPG.

The wasted spend comes from those companies, who, unable to access mains energy, are using old-fashioned energy supplies like oil. Not only is oil expensive, but is also an inefficient and dirty fuel to burn.

The alternative to oil for off-mains energy is LPG, a fuel with a lower cost price, less CO2 emissions and greater efficiency.

By switching to LPG, the sector could reduce its energy costs on fuel alone by over £9 million, a saving of 22%.

This saving rises to up to almost £12 million when the oil burning equipment is replaced by the much more fuel efficient LPG burners, giving a total saving of up to 27% when compared to oil.

With cost savings of up to 27%, when compared to the cost of switching from oil to LPG, the benefits are obvious, with the average business recouping their initial outlay in under a year.

The benefits of changing fuels aren’t just financial, there are also huge environmental benefits too as the switch to LPG can lead to a massive reduction in the sector’s carbon footprint.

With the sector currently using almost 800 million KW of energy a year from off-mains resources, generated from over 70 million litres of oil, it is producing the equivalent of 207, 000 tonnes of CO2 a year.

However, if that energy had been generated from LPG, the equivalent CO2 produced would be just under 160,000 tonnes, a reduction of over 47,000 tonnes of CO2 a year (23%).

This saving is equivalent to 23,500 flights from London to Sydney, or the weight of 470,000 baby elephants.

The figures are revealed in the ‘Flogas Energy Expenditure Report’, a piece of research initially carried out by Flogas to provide background information for its sales teams. However, the company was so shocked by the findings, it decided to share them with the sector as a whole.

This isn’t the only industry where savings could be made, with huge financial and carbon wastage taking place in all other industries using off-mains supplies.

However, it appears that many businesses aren’t aware of LPG or they are under the false impression that the switching process is complicated or expensive.

As the market leaders at converting off-mains businesses from oil to LPG, Flogas are well aware of customer perceptions.

Commenting on the findings, Lee Gannon, Flogas Managing Director said: “We initially carried out the research purely for internal purposes, but after seeing the figures, we felt the only responsible action was to share them with the industry. These are figures that everyone needs to see. Times are still tough, and there is a greater need than ever for businesses to reduce their energy costs and cut carbon emissions.

Gannon continued: “We find the biggest reasons that businesses burn oil is a lack of awareness that there is a cheaper, greener alternative, or because they are under the misconception that switching is expensive or difficult. By sharing these figures we hope to help the sector make savings, while at the same time making a large dent in their carbon footprint.”

About Flogas

Flogas Britain is a leading UK supplier of LPG (Liquefied Petroleum Gas) with 30 years’ experience of providing alternative energy solutions to domestic and commercial customers in the UK.

From LPG supply to cutting-edge renewable energies such as solar PV systems and wind turbines, Flogas delivers projects and services that are reliable, safe and expertly managed.

LPG is used for heating and cooking, industrial processes, and as a fuel for cars, trucks and fork lift trucks. Supply comes from either bulk tanks installed on customer premises or from a range of gas cylinders.

For more information, please visit www.flogas.co.uk

- Research carried out by Flogas in October 2014

- Oil price based on an average of the 2013 gasoil price

- LPG price based on Flogas pricing structure for large usage industrial customers

- Oil KW calculations based on generation of 11KW per litre of oil

- LPG KW calculation based on generation of 7.1 KW per litre of LPG

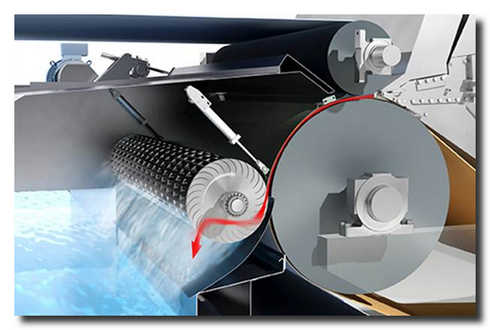

Valmet's new innovative energy recovery system exceeded expectations at Sofidel SPA in Italy

In order to increase energy efficiency of tissue production lines, Valmet has developed the Advantage ReTurne energy recovery system. This system does not only recover energy from the headbox jet power, but also returns it back to the process as electrical energy.

Valmet's Advantage ReTurne recovers energy from the Headbox jet stream and returns it back to the process as electrical power.

The first installation of Valmet's new innovation was recently started up at Sofidel's mill Delicarta Valdottavo, Italy and has already proved to fully meet the expectations.

Sofidel is the first Italian company and the first toilet paper and household tissue company in the world to have joined Climate Savers, the international program promoted by WWF, to voluntarily adopt plans to reduce emissions of greenhouse gases, using innovative strategies and technologies. It is therefore important to find new innovative solutions to reduce the environmental impact of their production.

"The first installation of the Advantage ReTurne energy saving system has been a positive experience for us. Its energy saving capabilities turned out to be better than we hoped for and well in line with our target to further reduce our CO2 emissions before the end of 2020," Simone Capuano, Vice Chief Technical Officer, Sofidel.

"We had high expectations of the results from the first installation of the Advantage ReTurne system which was substantially exceeded. The installation went smoothly and the machine was running at full speed within five days. But the most exiting was that the energy recovery proved to be above guaranteed level," Jan Erikson, VP Sales, Valmet

Technical information

The Advantage ReTurne energy recovery system is installed in the forming section. It is unique in that sense that it recovers 50% of the energy from the headbox drainage water and via a generator converts it to electrical power which supplies the sectional drives. The Advantage ReTurne do not affect the formation of the paper or the tissue making process, it is easy to handle and has low maintenance need. This new innovation is most efficient installed in new or existing tissue machines.

Information about Sofidel

The Sofidel Group is, today, the second largest European manufacturer of tissue paper (paper products for sanitary and domestic use) and the sixth largest in the world. It was founded over 45 years ago (1966) and today boasts 27 subsidiaries in 13 countries - Italy, Spain, Sweden, The United Kingdom, Belgium, France, Croatia, Germany, Poland, Romania, Greece, Turkey and the USA. It has about 5000 employees and a consolidated turnover of € 1,699 million (2013) and a capacity of over a million tonnes a year.

For further information, please contact:

Jan Erikson, VP Tissue Sales, Valmet, Tel. +46 705 17 14 90

Johan Björn, Sales Manager, Valmet, Tel. +46 703 17 12 16

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 11,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

The company has over 200 years of industrial history and was reborn through the demerger of the pulp, paper and power businesses from Metso Group in December 2013. Valmet's net sales in 2013 were approximately EUR 2.6 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Metso to increase its footprint in the Middle East by opening new sales offices and valve service centers in the United Arab Emirates and Qatar

Metso is opening new sales offices and service centers in the Abu Dhabi, United Arab Emirates, and Doha, Qatar, to support the strategy to grow its valve and field device business and to strengthen its service capabilities in the Middle East for the petrochemical, energy, oil and gas, and pulp and paper industries.

Metso is opening new sales offices and service centers in the Abu Dhabi, United Arab Emirates, and Doha, Qatar, to support the strategy to grow its valve and field device business and to strengthen its service capabilities in the Middle East for the petrochemical, energy, oil and gas, and pulp and paper industries.

The new service centers offer the latest technology and know-how to carry out high-quality maintenance and repair work on Metso and third-party devices, including valves, actuators, smart devices and pumps. Through the new sales offices, Metso can offer its local customers a full service and business solution portfolio, including market-leading valve solutions, maintenance of equipment and even plant-wide control system optimization.

Metso is a value-adding partner for all project key stakeholders, including operators, engineering, procurement and construction contractors, and original equipment manufacturers. Over the years, Metso's business has grown steadily also in the highly competitive Middle Eastern valve market.

"We offer industry-leading flow control know-how for even the most challenging applications. Metso's assets are reliability, expertise and a wide product portfolio. For example, in a typical petrochemical project, Metso's product range covers up to 90% of the needed valves," explains Kalle Autto, Vice President, Middle East Market Area, Metso.

"Our new sales offices and service centers will considerably improve our customer service capability in the region. Our customers will have easy access to our technical and process know-how related to flow control solutions, including process improvements and debottlenecking as well as project management," adds Autto.

In addition to repair and refurbishment, both service centers offer upgrades, spare parts, training programs, field support and diagnostic services. Building on these technical services, the centers also offer business solutions, such as Intelligent Shutdown and Intelligent Maintenance as well as Device Management and Control Performance targeting in improved maintenance and production efficiency. The Control Performance solution, used especially in the extensive installations in the Middle East, is based on Metso's award-winning PlantTriage software, which continuously monitors and analyzes the customer's process and control information and offers guidance on which parts to develop further.

Leading flow control technology for improved safety and sustainability

Metso has a long track record of delivering engineered performance and reliability to the oil and gas, pulp and paper, and power customers through its leading product brands - Neles®, Jamesbury® and Mapag® - and has delivered millions of valves, control valves, and on-off valves globally over the last 90 years. Additionally, Metso has become one of the leading suppliers of intelligent valve controllers.

Metso's extensive flow control services offering covers business solutions and services that optimize equipment use and cost of ownership. Metso's valve technology centers and valve production facilities are located in Finland, the United States, Germany, China, South Korea, India and Brazil. By the end of 2014, Metso will have more than 40 valve and field device service centers worldwide.

Metso in the Middle East

In the Middle East, Metso currently serves the petrochemical, energy, oil and gas, and selected other industries. It has sales and service operations in the United Arab Emirates, Qatar, Bahrain, Saudi Arabia and Kuwait.

Metso is a leading process performance provider, with customers in the mining, oil and gas, and aggregates industries. Metso's cutting-edge services and solutions improve availability and reliability in minerals processing and flow control, providing sustainable process and profit improvements. Metso is listed on the NASDAQ OMX Helsinki, Finland. In 2013, Metso's net sales totaled EUR 3.8 billion. Metso employs approximately 16,000 industry experts in 50 countries. Expect results.

www.metso.com , www.twitter.com/metsogroup

For further information, please contact:

Kalle Autto, Vice President, Flow Control, Middle East Market Area, Metso, tel: +971 4 8836974, email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Jussi Ollila, Vice President, Global Marketing and Communications, Metso Corporation, tel: +358 20 484 3212, email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Lenzing Group: Persistently Difficult Market Environment, Cost Savings Measures Positively Impact Results

The Lenzing Group is working to counteract the ongoing difficult market environment prevailing in the fiber industry. Sales and earnings declined in the first nine months of 2014 compared to the prior-year performance, but cost savings are having a positive impact. This led to a slight earnings improvement in the third quarter of 2014, the first time in about two years. Further cost reductions are planned in light of the fact that no significant impetus is expected from the market.

The Lenzing Group is working to counteract the ongoing difficult market environment prevailing in the fiber industry. Sales and earnings declined in the first nine months of 2014 compared to the prior-year performance, but cost savings are having a positive impact. This led to a slight earnings improvement in the third quarter of 2014, the first time in about two years. Further cost reductions are planned in light of the fact that no significant impetus is expected from the market.

- Q1-3 EBITDA of EUR 159.8 mn (down 16% from the previous year)

Ongoing weak fiber prices burden Q1-3 sales and earnings

The decline in the average fiber selling prices and the high volatility on the fiber market continue to negatively impact the company’s business operations. Consolidated sales decreased by 6.2% to EUR 1,357.7 mn in the first three quarters of 2014, down from EUR 1,447.0 mn in the previous year. More than half of the sales drop is due to the non-recurring effects relating to the disposal of the Business Unit Plastics in 2013. Consolidated sales were down by 2.8% in a like-for-like comparison. Average fiber selling prices of the Lenzing Group fell to 1.55 EUR/kg compared to 1.73 EUR/kg in the first three quarters of 2013. The price decline could not be fully offset by increasing fiber production and sales volumes, in part as a result of the successful start-up of the new TENCEL® fiber manufacturing facility at the Lenzing site. Fiber sales volumes rose by 7% year-on-year to 706,900 tons in the first nine months of 2014.

In a like-for-like comparison of continuing operations, consolidated EBITDA1 in the first nine months of the year amounted to EUR 159.8 mn, a 16.0% decrease compared to EUR 190.2 mn for Q1-3 2013. This corresponded to an EBITDA margin of 11.8% (Q1-3 2013: 13.6%). Consolidated nine-month earnings before interest and taxes (EBIT) amounted to EUR 69.5 mn, a drop of 34.8% from EUR 106.6 mn in the previous year. This comprised an EBIT margin of 5.1% (Q1-3 2013: 7.6%). As a consequence of the excelLENZ program, the number of employees working for the Lenzing Group fell to 6,352 people as at September 30, 2014 (December 31, 2013: 6,675) despite the full operation of the new TENCEL® fiber production plant in Lenzing.

1 Earnings before interest, taxes, depreciation on property, plant and equipment and amortization of intangible assets and before income from the release of investment grants.

Third-quarter earnings reflect cost reductions

The third-quarter 2014 performance of the Lenzing Group was marked by a slight year-on-year earnings improvement as well as in comparison to the second quarter of 2014. “The measures are succeeding. The earnings improvement is mainly attributable to the excelLENZ cost-cutting drive but also from the first fiber sales volumes produced by the new TENCEL® fiber plant in Lenzing”, says Lenzing CEO Peter Untersperger.

In spite of higher sales volumes, consolidated sales in the third quarter of 2014 stagnated at EUR 457.7 mn compared to the prior-year level of EUR 457.1 mn, which is due to the lower average fiber selling prices. Nevertheless, third-quarter EBITDA rose to EUR 68.0 mn (Q3 2013: EUR 61.8 mn), and EBIT in the third quarter of 2014 totaled EUR 37.1 mn (Q3 2013: EUR 33.4 mn), whereas EBT improved to EUR 33.3 mn from the figure of EUR 28.2 mn in the prior-year quarter.

Implementation of further cost savings

“We expect cost savings exceeding EUR 90 mn for the entire year 2014, of which about one quarter involves personnel expenses. The remaining cost decreases equally relate to reduction in material costs and savings derived from efficiency projects to cut general and administrative expenses”, adds CEO Untersperger. “Planning work has begun to enable a further improvement of the Lenzing Group’s cost structure to be achieved in 2015. Starting in 2016 we will achieve sustainable cost reductions of over EUR 160 mn p.a. These measures are designed to safeguard the long-term competitive strength of the company and its self-financing capacity for future investments.”

Outlook Lenzing Group

The global market for man-made cellulose fibers will continue to be impacted in the upcoming months by low pulp prices and surplus fiber production capacities against the backdrop of good volume demand.

The successful ramp-up of the TENCEL® fiber plant in Lenzing, the initiated improvements in the product mix, and the strong expansion of marketing and sales activities along the entire value chain will improve the company’s market position and its relative competitive strength. In addition to an intensification of the excelLENZ cost reduction program, the realignment initiative in the fields of Lenzing Technik, site maintenance and repair services will make an important contribution towards achieving operational improvements at Lenzing.

The Lenzing Group

The Lenzing Group is a world market leader with headquarters in Austria, production sites in all major markets as well as a worldwide network of sales and marketing offices. Lenzing supplies the global textile and nonwovens industry with high-quality man-made cellulose fibers. The portfolio ranges from dissolving pulp, standard and specialty cellulose fibers to engineering services.

Lenzing quality and innovative strength set global standards for man-made cellulose fibers. With 75 years of experience in fiber production, the Lenzing Group is the only company worldwide combining the manufacturing of all three man-made cellulose fiber generations on a large industrial scale under one roof – from the classic viscose to modal and lyocell (TENCEL®) fibers. The success of the Lenzing Group results from a unique combination of consistent customer orientation together with its leadership in innovation, technology and quality. Lenzing is committed to the principle of sustainable management and very high environmental standards.

Lenzing's core business fibers is complemented by our activities in the business field engineering.

The Interim Report 01-09/2014 is available for download via this link

Key Figures Lenzing Group 2013:

Sales: EUR 1.91 bn

Export share: 90,8%

Fiber sales volumes: 890,000 tons

Staff: 6,675

for more info please contact:

Stephanie Kniep

Head of Investor Relations

Phone: +43 (0) 7672 701-4032

This email address is being protected from spambots. You need JavaScript enabled to view it.

'Lost' British Paper Brand Relaunched by James Cropper Paper

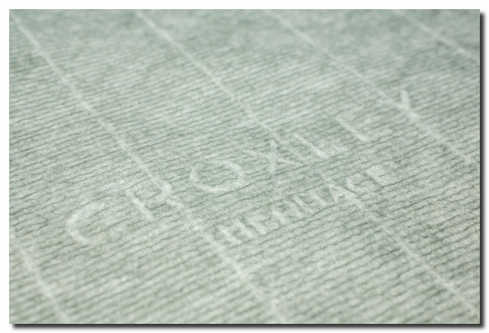

Croxley Heritage Re-launched in 2015

Prestigious British paper brand returns with a mission to reignite the romance in quality stationery.

One of the great British stationery brands Croxley Heritage is to be reintroduced to the desks of discerning business and private paper buyers via a relaunch at Paperworld, Frankfurt between Saturday 31 January – Tuesday 3 February 2015. Inspired by the original brands of John Dickinson & Co. Ltd of London, established in 1804, the stationery line will be reactivated by luxury paper manufacturer, James Cropper.

Inventor of continuous mechanised paper production techniques, John Dickinson (1782-1869) established mills across the world at the height of his powers as a leading, Victorian industrialist. However, it was his mill at Croxley Green, Hertfordshire on the banks of the Grand Union canal that gave some of the famous Dickinson brands - including Croxley – their names, with paper running off the production line there for 150 years until 1980.

Having been recently acquired by James Cropper – based in Cumbria at the heart of England’s Lake District – 2015 sees Croxley Heritage re-launched to carry the values and traditions of one of the world’s oldest and most sought after paper products, with the brand’s custodians encouraging buyers to rediscover the romance of beautifully made, traditional stationery.

Chris Brown, Commercial Director of James Cropper, said: “Croxley Heritage is a name synonymous with the best traditions of British paper manufacturing, born of a pioneering paper maker, John Dickinson. Like Dickinson, James Cropper - great-great-great grandfather of our Chairman Mark Cropper – believed in the production of only the highest quality papers. It is fitting that we have the opportunity to take this brand back onto the market in the best of their founding traditions.”

The paper fibre used to make the contemporary versions of Croxley Heritage will be comprised of 90% post-consumer waste and 10% reclaimed cup fibre from James Cropper’s own reclaimed fibre facility, opened last year following a £5million investment. The production process uses Hydro Power from a newly commissioned hydro plant on the river Kent (developed with Ellergreen Energy); ensuring Croxley Heritage is as clean to produce as it appears in its final form. Croxley Heritage is a watermarked paper range in a neutral colour palette – white, cream, silver, wedgwood – available in a selection of wove, laid and linen finishes.

Phil Wild, CEO of James Cropper, said: “Business users looking for a paper to reflect their credentials will find the Croxley Heritage range perfect for letterheads, business cards and other uses, but we also recognise that sustainable sourcing is also a reputational issue for all of our customers. The production process has been carefully designed to ensure the environmental impact of every sheet of paper is dramatically reduced by using state-of-the-art recycling technologies and sustainable energy procurement.”

ABOUT JAMES CROPPER & TECHNICAL FIBRE PRODUCTS (TFP):

James Cropper is based in the Lake District, England’s first and foremost National Park, with a paper-making heritage that started in 1845. Since its inception the business has been carefully stewarded and nurtured by six generations of the Cropper family.

Today the business is renowned globally for its luxury packaging papers, which accompany many of the world’s most exclusive brands, while the world’s leading artists, galleries and museums use its framing and archival boards alongside its range of conventional artists materials. As well as paper products, James Cropper also manufactures nonwovens from carbon, glass and polymer fibres, which play a key part in production of composites in the automotive, energy and aerospace sectors.

Technical Fibre Products (TFP) is a leading nonwoven manufacturer, offering a broad range of high quality, technically advanced nonwovens into the composites market, which can be customised to meet specific application requirements. Established nearly 30 years ago, TFP primarily operates within the automotive, and aerospace composite markets while also providing effective solutions in the defence, energy, consumer electronics, industrial, construction and healthcare markets. Utilising extensive materials knowledge within polymers, particulates & speciality fibres together with high specification lamination, metal fibre coating and converting capabilities, TFP provide a wide range of customised solutions.

To find out more about the innovative production methods, product range, responsible manufacturing principles and history of James Cropper and Technical Fibre Products, please visit www.jamescropper.com and www.tfpglobal.com

Valmet launches on-site paper machine roll coating service in Japan with Tocalo

Valmet has signed a license agreement with Tocalo to manufacture for the Japanese market Valmet's DryOnyx H on-site release coating for drying cylinder applications for paper machines. Tocalo has extensive experience in on-site roll services in Japan, and Valmet's technology will complement Tocalo's existing on-site range. The agreement was signed in August 2014, and operations will start at the beginning of December 2014.

DryOnyx H release coating on drying cylinder

DryOnyx H is a special release coating for drying and cooling cylinders. "Its functional surface chemistry has excellent antifouling properties as well as superior doctoring resistance. This means it has a long lifetime and provides extended service intervals," says Samppa Ahmaniemi, director of Roll Covers at Valmet. He continues: "We have already proved this. We have over 300 references globally within our paper and board customers."

"We see good market opportunities for this kind of coating service," explains Daisuke Inoue, Supervisor, Global Business Development at Tocalo. "DryOnyx H has a unique polymer composition which gives it a short coating time. This provides remarkable savings and benefits for on-site work. The coating also has excellent release properties and corrosion resistance. Our license agreement with Valmet will strengthen our position in the Japanese market among paper and board customers."

Information about Tocalo

TOCALO Co., Ltd. was originally established as Toyo Carolizing Industry Co., Ltd. in 1951. With introducing thermal spraying technology as the core business from its early stage, TOCALO has made a continuous progress and been a key player in surface modification field since its foundation.

VALMET CORPORATION

For further information, please contact:

Samppa Ahmaniemi, Director, Roll Covers, Services, Valmet, tel. +358 400 461 417, This email address is being protected from spambots. You need JavaScript enabled to view it.

Daisuke Inoue, Supervisor, Global Business, Tocalo Co., Ltd., tel. +81 78 411 5561,

This email address is being protected from spambots. You need JavaScript enabled to view it.

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 11,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

The company has over 200 years of industrial history and was reborn through the demerger of the pulp, paper and power businesses from Metso Group in December 2013. Valmet's net sales in 2013 were approximately EUR 2.6 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Read more www.valmet.com , www.twitter.com/valmetglobal

Global and Chinese Enzyme for Pulp & Paper Industry Report 2014-2019

![]() Research and Markets (http://www.researchandmarkets.com/research/9hdfm2/global_and) has announced the addition of the "Global and Chinese Enzyme for Pulp & Paper Industry Report 2014" report to their offering.

Research and Markets (http://www.researchandmarkets.com/research/9hdfm2/global_and) has announced the addition of the "Global and Chinese Enzyme for Pulp & Paper Industry Report 2014" report to their offering.

“Global and Chinese Enzyme for Pulp & Paper Industry Report 2014”

The Global and Chinese Enzyme for Pulp & Paper Industry Report 2014 is a professional and in-depth study on the current state of the global enzyme for pulp and paper industry with a focus on the Chinese situation.

The report provides a basic overview of the industry including definitions, classifications, applications and industry chain structure. The enzyme for pulp and paper market analysis is provided for both the international and Chinese domestic situations including development trends, competitive landscape analysis, key regions development status and a comparison analysis between the international and Chinese markets.

Development policies and plans are also discussed and manufacturing processes and cost structures analyzed. Enzyme for pulp and paper industry import/export consumption, supply and demand figures and cost price and production value gross margins are also provided.

The report focuses on fourteen industry players providing information such as company profiles, product picture and specification, capacity production, price, cost, production value and contact information. Upstream raw materials and equipment and downstream demand analysis is also carried out. The enzyme for pulp and paper industry development trends and marketing channels are analyzed. Finally the feasibility of new investment projects are assessed and overall research conclusions offered.

Key Topics Covered:

- Enzyme for Pulp & Paper Industry Overview

- Asia Enzyme for Pulp & Paper Market Analysis

- North America Enzyme for Pulp & Paper Market Analysis

- Europe Enzyme for Pulp & Paper Market Analysis

- Global Enzyme for Pulp & Paper Market Analysis

- Enzyme for Pulp & Paper Industry Development Trend

- Enzyme for Pulp & Paper New Project Investment Feasibility Analysis

- Global Enzyme for Pulp & Paper Industry Research Conclusions

Companies Mentioned

- Advanced Enzymes

- Anil Bioplus

- Anthem Cellutions

- Buckman

- Dyadic

- EDT

- Epygen

- Kdnbio

- Leveking

- Om-biosciences

- Sukehan

- Verenium(BASF)

- Yiduoli

- Youtellbio

For more information visit http://www.researchandmarkets.com/research/9hdfm2/global_and

Contacts

Research and Markets

Laura Wood, Senior Manager

This email address is being protected from spambots. You need JavaScript enabled to view it.

For E.S.T Office Hours Call 1-917-300-0470

For U.S./CAN Toll Free Call 1-800-526-8630

For GMT Office Hours Call +353-1-416-8900

U.S. Fax: 646-607-1907

Fax (outside U.S.): +353-1-481-1716